Powerful, Easy-to-Use, Lightning-Fast

SPC and CMM Data Collection Software

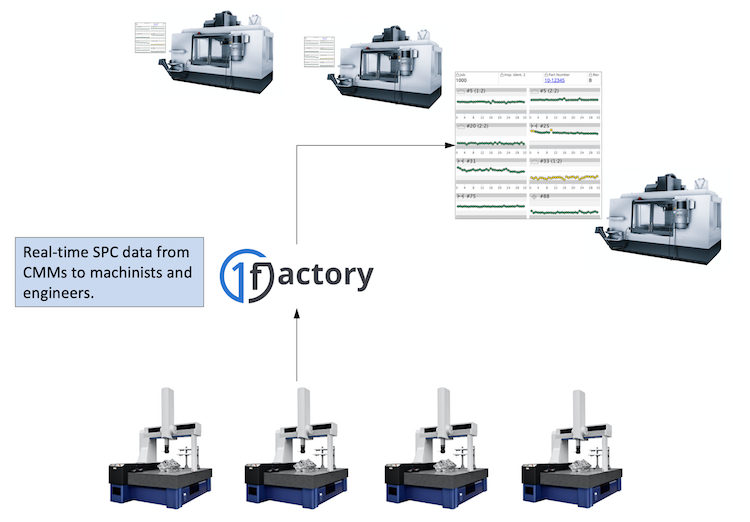

Automate data capture from coordinate measuring machines (CMMs), vision systems, and other inspection equipment. Load data in seconds and deliver real-time SPC charts to factory-floor users so they can correct manufacturing processes, address drift and prevent defects.

VERIFY INCOMING COMPONENT QUALITY. REDUCE DEFECT RISK AND INSPECTION COST.

EFFICIENCY & COST SAVINGS

“Overall, I am very happy the implementation of the 1Factory software. Our operators love the ease of use, and the fact that they no longer have to transfer CMM data by hand. I only wish our customers would also make the switch from the current data collection service that we are forced to use.”

Harrison M., Quality Engineer

OVERVIEW

WHAT IS CMM DATA COLLECTION?

Modern manufacturing quality control relies heavily on precision measurement equipment - from CMMs and vision systems to profilometers and digital gages.

Each measurement device generates critical dimensional data that must be analyzed for process stability and compiled into customer reports.

For complex parts with hundreds of parameters, this data serves as the foundation for process control and quality documentation.

However, the true value of these sophisticated measurements can only be realized when data flows seamlessly from measurement to analysis.

WHAT MAKES CMM DATA COLLECTION CHALLENGING?

Manufacturers face mounting complexity in collecting and analyzing measurement data across diverse equipment types.

CMMs present particular challenges, with each machine outputting data in proprietary formats and handling GD&T results and multi-place dimensions differently.

In high-mix, high-volume environments with multiple CMMs measuring hundreds of parameters per part, manual data transfer becomes unsustainable.

This leads to delayed detection of process drifts and out-of-specification conditions, often discovered only after parts have shipped.

Quality teams waste valuable time on manual data entry instead of focusing on process improvement.

THE 1FACTORY CMM DATA COLLECTION SOLUTION

1factory transforms measurement data collection through intelligent auto-upload capabilities that connect directly to CMMs and other measurement devices.

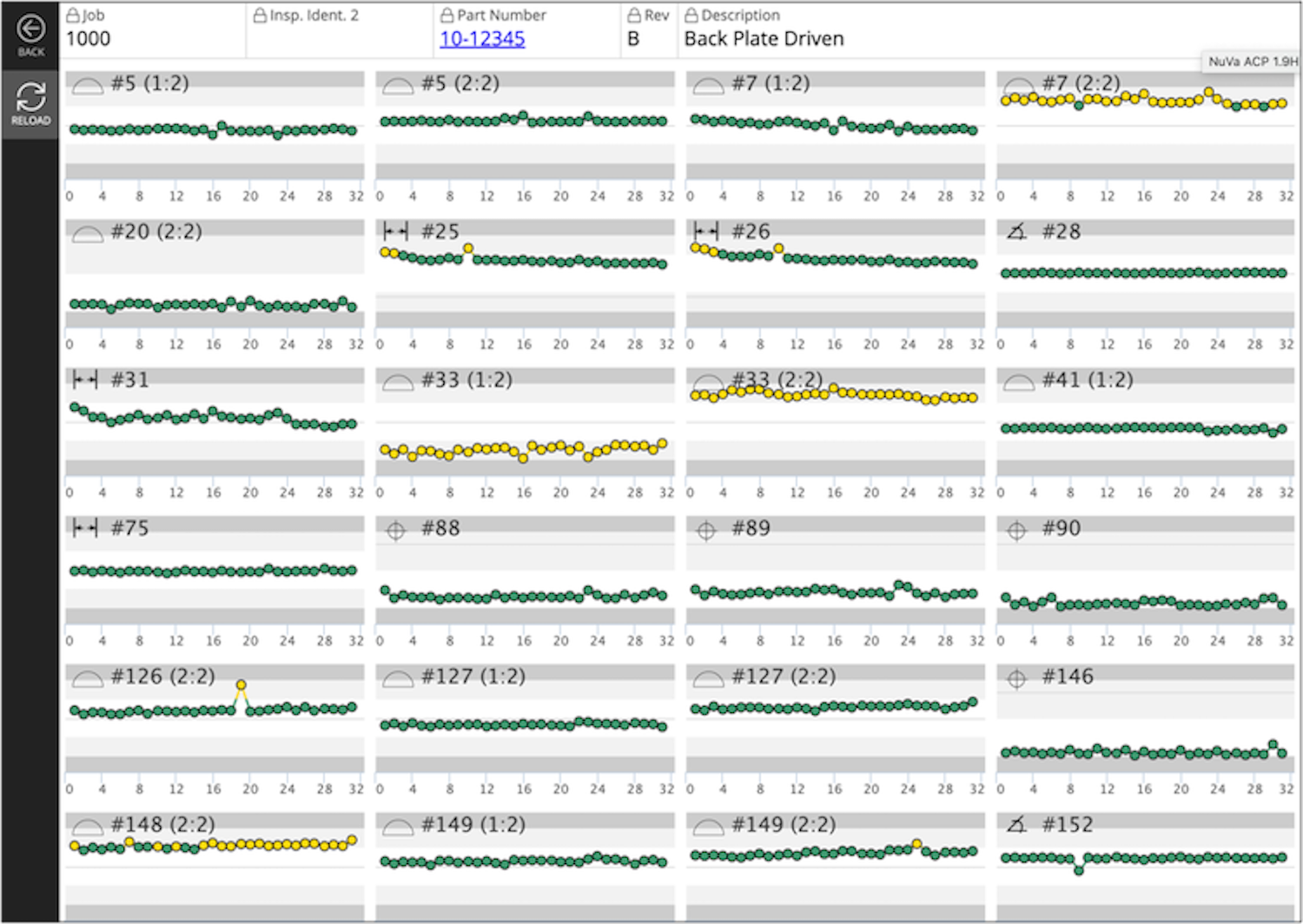

Our platform automatically interprets diverse data formats and instantly generates live SPC charts and process analysis, enabling real-time monitoring of critical dimensions.

Quality teams gain immediate visibility into process trends through powerful run charts and Western Electric rule detection, while eliminating manual data entry and associated errors.

For customer reporting, our system generates comprehensive documentation with a single click.

This automated approach not only prevents quality escapes through early detection but also frees quality personnel to focus on process improvement instead of data transcription.

FEATURES

1Fully Automated CMM Data Import

Fully automate data collection from CMMs, Vision Systems, and connected digital gages. Data is imported as soon as the CMM outputs the file. Improve speed and accuracy of manufacturing quality control data collection. Supported devices include Zeiss, Keyence, PCDMIS, Mitutoyo and many more.

2Select and Upload CMM Data Import

Partially automate CMM data import. Import data by selecting CMM output files. Load data for one part or multiple parts. Load either (1) one file per measured part, or (2) multiple files per measured part.

3Multi-Parameter SPC

Instantly generate live SPC charts and enable real-time control of critical features. Detect trends and anomalies quickly at the point of manufacture. Notify engineers and managers of out-of-control events.

4Tabulated Plans

Easily manage tabulated drawings with thousands of configurations via a single Inspection Plan for the family. 1factory automatically generates the inspection sheet for each configuration with all required common and part-specific features.

CASE STUDIES

Ultra Machining Company (UMC)

Ultra Machining Company (UMC) is a manufacturer of high-precision components for medical device, aerospace, and defense applications. Products manufactured by UMC are complex, with 100 — 800 features per product. UMC's Quality Control team operates nearly 30 CMM and Vision Systems.

"OK, prove it. This was the gauntlet thrown down by UMC to 1Factory - a challenge to automate the data output of nearly 30 CMMs straight into 1Factory in real time."

"This capability means that every data point from every touch of a CMM probe or scan of a vision machine is visible almost instantly to every machinist at every workstation on the shop floor. Once UMC's inspection data is in 1Factory, the software analyzes the data and creates a run chart and histogram that shows which part features present the highest risk of failure."

Read the full Modern Machine Shop Feature on 1factory's work with UMC.

EASY TO USE. LIGHTNING FAST.

INTUITIVE DESIGN

1factory is designed for the front-line of quality control with design inputs and ideas from our users. 1factory's intuitive navigation and best-in-class screen-designs make training a breeze. Training and full-deployment takes under two hours with no disruption to operations.

LIGHTNING FAST SPEED

1factory is engineered to be lightning-fast. We serve customers all over the world 24 hours a day, 7 seven days a week, 365 days a year. Our customers in United States, Mexico, Canada, Israel, China, South Africa, Denmark, UK, India, Malaysia, Taiwan all enjoy lightning-fast data collection and powerful real-time analytics.

SECURE AND RELIABLE

SECURITY

1factory is hosted on AWS GovCloud. The AWS GovCloud service is an isolated Amazon region designed to host sensitive data and regulated workloads, including International Traffic in Arms Regulations (ITAR) data.

All customer data transfer from client to server is encrypted over standard HTTPS/TLS 1.2, using a certificate with 2048-bit RSA public key / SHA-256 with RSA encryption. All customer data is encrypted at rest. Data (e.g. Part Numbers, Measurements etc.) are stored in an encrypted Amazon RDS instance. Drawings, Raw Material Certificates etc. are stored on encrypted Elastic Block Storage (EBS) volumes. Drawings and other documents may be additionally encrypted with individual encryption keys.

1factory complies with all NIST-800-171 requirements. 1factory also maintains a SOC2 Type 2 certification, and a copy is available upon request.

RELIABILITY

1factory has been engineered to be highly reliable, scalable and available. Over 200 million parts have been inspected with 1factory by customers in 33 countries.

1factory has delivered an uptime of >99.99% over the last 8 years. We use a third-party service to monitor system uptime, and our customers can view our uptime and availability metrics in real time.

1factory backs-up database with a daily snapshot. Files are stored on redundant hard-drives and backed up via daily snapshots.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & DEFENSE

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS