Powerful, Easy-to-Use, Lightning-Fast

NCR, CAPA, SCAR and Complaint Management Software

Easily record, manage, and analyze Nonconformance Reports (NCRs), Corrective & Preventive Action Reports (CAPAs), Supplier Corrective Action Reports (SCARs), and Customer Complaints. Assign tasks, track status, and ensure timely completion. Drive accountability with automated notifications and escalations.

Resolve quality issues faster, prevent recurrence, reduce cost of poor quality, and maintain full compliance.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & INDUSTRIAL

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS

RESOLVE ISSUES QUICKLY. ANALYZE TRENDS. PREVENT RECURRENCE.

SIMPLE YET ELEGANT APPROACH TO QUALITY

“The software is easy to use and learn. I have been in the Quality Assurance world for quite some time now and find that both new and seasoned persons would appreciate the simplistic, yet elegant, approach to quality. The simplistic way that it produces reporting is a great and useful tool for anyone looking to gain or maintain compliance with regulatory bodies (ISO/AS/IATF) as well as keeping customer satisfaction high with quick reporting/number assisgnments to CAPA/8D reports.”

G. Mejia, Camisasca Automotive

KEY ISSUE MANAGEMENT FEATURES

1 Nonconformances (NCRs,)

Easily create and manage nonconformances for manufacturing or engineering caused defects, deviations, customer returns, audit findings, safety problems etc. Autopopulate NCR details from Inspections. Assign action-items, and use automated reminders to ensure timely resolution.

2 Corrective Actions (CAPA, SCARS)

Initiate CAPAs and SCARs from NCRs. Setup CAPA templates to guide the user, and ensure a consistent problem-solving process. Track CAPA and SCAR progress, and use automatic reminders to ensure timely resolution. Review and Approve.

3 Supplier Corrective Actions (SCARs)

Request Corrective Actions from suppliers using the 8D process. Work together with suppliers to resolve problems and prevent recurrence. Ensure all 8D sections are filled-out, supplier actions are completed and effectiveness is verified prior to closing out the corrective action.

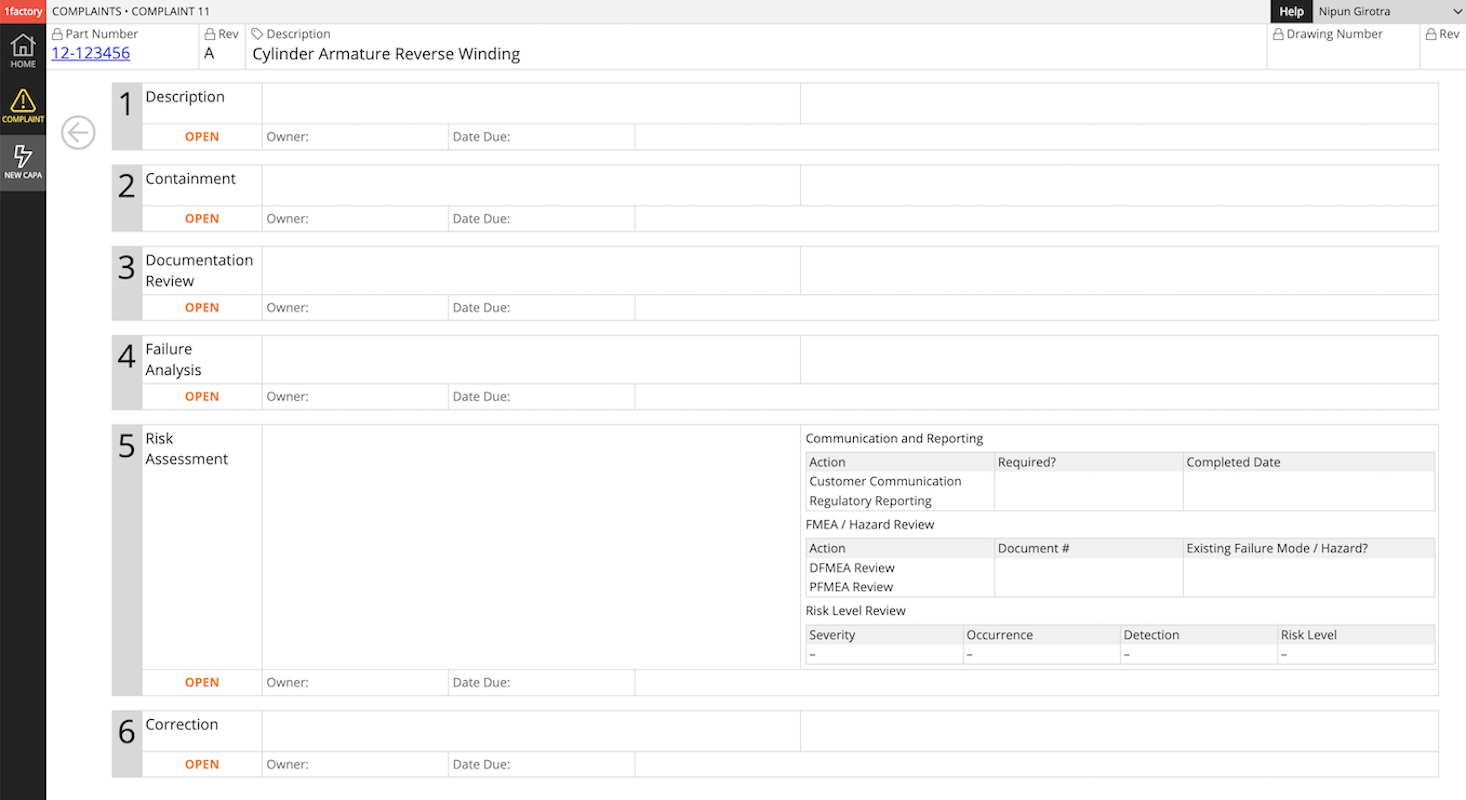

4 Complaints

Record and track product failures or deficiencies reported by field service teams and customers. Track reported issues from initial complaint through Investigation (Review of Device /Lot History Record, Failure Analysis), Risk Assessment, Containment, Corrective Action, and Preventive Action. Assign and track actions

5 Audit Findings

Manage audit findings and associated tasks. Ensure compliance and readiness for customer or regulatory audits. Support a continuous improvement culture by enabling team-members to log and track business process improvement actions.

6 Task Management

Assign tasks with due-dates at any point in a non-conformance (NCR) or CAPA process for investigation, correction, containment, rework and other actions. Automate reminders and follow-ups to ensure tasks are completed.

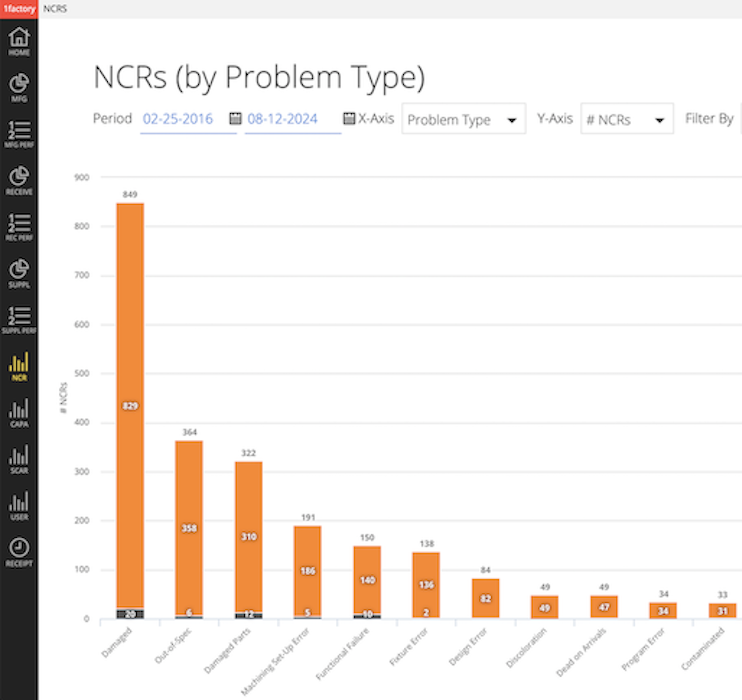

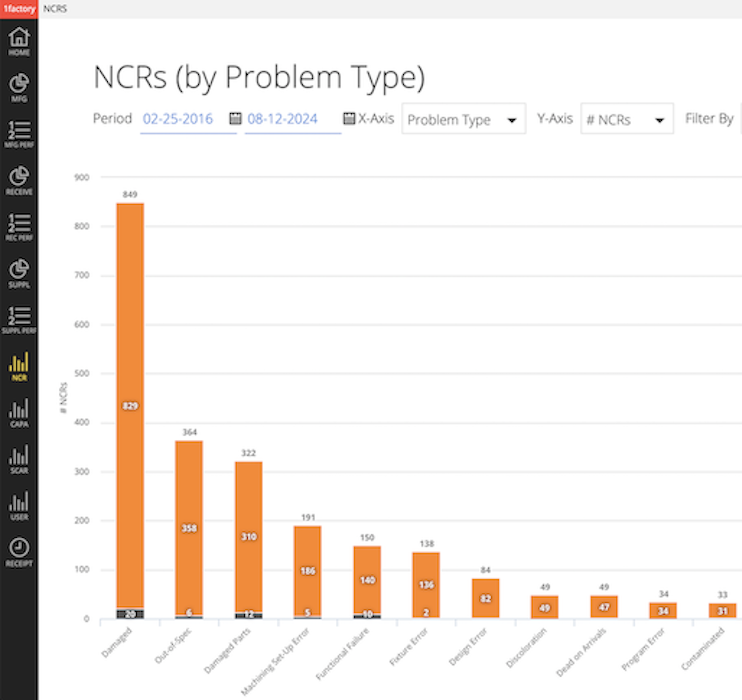

7 Real Time Analytics

Instantly analyze non-conformances, CAPAs, SCARs, Complaints etc. with built-in lightning-fast analytics without expensive 3rd-party BI tools. Pareto and trend data by Part Number, Customer, Supplier, Defect Code, Root Cause. Quickly identify and resolve problems.

CASE STUDIES

Ultra Machining Company (UMC)- Manufacturing QC

UMC is a manufacturer of high-precision components for medical device, aerospace, and defense applications. The products are complex, with 100 — 800 features per product.

With 1factory, UMC successfully consolidated 5 separate QC systems into 1. Today, data is automatically uploaded from 20 CMMs and 8 VCMMs, 24 hours a day. Over 1 million measurements are recorded in 1factory each month. Auto-ballooning speeds up FAI creation. And hours are saved from each PPAP package creation.

Watch a 4-minute video to hear first-hand experiences from the cross-functional UMC team: Machinists, Quality Engineers, Director of Quality, VP of IT, and VP of Operations.

EASY TO USE. LIGHTNING FAST. SECURE & RELIABLE

INTUITIVE DESIGN & LIGHTNING FAST SPEED

1Factory's intuitive interface and streamlined workflows make training effortless - most teams achieve full deployment in under two hours with zero operational disruption.

Speed is non-negotiable on the shop floor. Every interaction - from data entry to ballooning to search - happens instantaneously. Your manufacturing operations run at full pace, never waiting on software. With 24/7/365 global availability and real-time analytics, 1Factory keeps your quality operations moving at the speed of production.

SECURITY & RELIABILITY

1Factory meets the security standards that matter to regulated manufacturers: ITAR-compliant hosting on AWS GovCloud, full NIST 800-171 compliance, and SOC 2 Type 2 certification. Your quality data stays protected and audit-ready.

Over the past decade, 1Factory has maintained >99.99% uptime - because we understand that your quality system can't afford downtime. Data encryption, daily database snapshots, and redundant file storage ensure your critical quality records are always protected and recoverable.